introduction

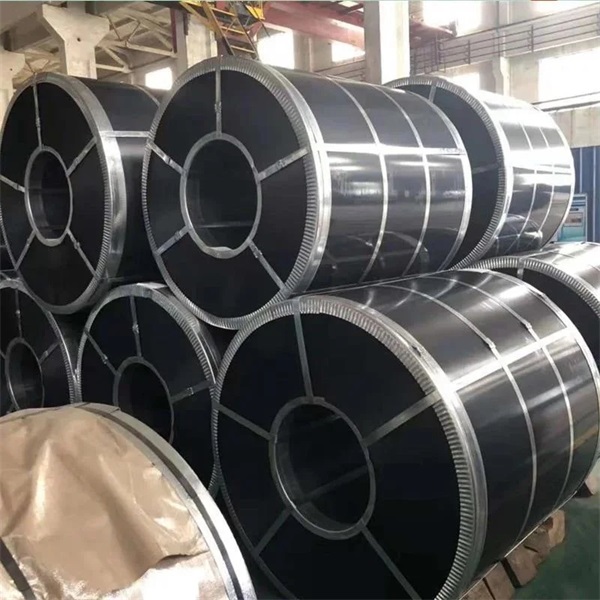

Thickness of Cold Rolled Carbon Steel Pipe

Abstract:

The thickness of cold rolled carbon steel pipe plays a vital role in determining the durability and performance of the pipe. This article aims to provide readers with comprehensive information regarding this important aspect of carbon steel pipes. By exploring the four main aspects related to the thickness, we will delve into the significance of this factor and its impact on various industrial applications. Understanding the thickness of cold rolled carbon steel pipe is essential for professionals in fields such as construction, transportation, and manufacturing.

1. Importance of ThicknessThe Influence of Thickness on Pipe Strength and Durability

The thickness of a cold rolled carbon steel pipe directly affects its strength and durability. A thicker pipe offers higher resistance to external forces and pressure, reducing the risk of structural failures. It provides better support for fluids or gases flowing through the pipe, maintaining its integrity even under intense conditions. Additionally, a thicker pipe minimizes the chances of corrosion, prolonging the lifespan of the pipe and ensuring long-term reliability.

Thermal Conductivity and Insulation Properties

The thickness of a cold rolled carbon steel pipe significantly impacts its thermal conductivity. Thicker pipes possess higher thermal conductivity, allowing for efficient heat transfer. This characteristic is crucial in applications where heat dissipation or transfer is required, such as in heat exchangers or piping systems used in power plants. Conversely, thicker pipes can also serve as effective insulation, preventing heat loss in applications that require temperature maintenance or control.

Absorption of Mechanical Vibrations

Thickness plays a crucial role in the pipe's ability to absorb and dampen mechanical vibrations. Thicker pipes have a higher natural frequency, allowing them to effectively dissipate vibrations and maintain structural stability. This characteristic is particularly important in industries where machinery or equipment generates significant vibrations, such as in manufacturing or automotive applications. The appropriate thickness of cold rolled carbon steel pipes can help minimize the impact of vibrations on surrounding structures.

2. Factors Affecting ThicknessManufacturing Techniques and Standards

The thickness of cold rolled carbon steel pipes is determined by various manufacturing techniques and adherence to industry standards. Different methods, such as hot rolling or cold rolling, can influence the final thickness of the pipes. Additionally, compliance with international standards and specifications ensures uniformity and accuracy in the thickness of the pipes produced. Professionals must be aware of these factors to select pipes that meet their specific requirements.

Application Requirements and Load Considerations

The intended application and the anticipated load on the pipe significantly influence the required thickness. Industries with high-pressure or corrosive environments typically require thicker pipes to ensure optimal performance and safety. Professionals must consider various factors, including fluid characteristics, operating conditions, and regulatory standards, when determining the appropriate thickness for their specific applications.

Cost and Material Efficiency

Balancing cost and material efficiency is another key factor when deciding the thickness of cold rolled carbon steel pipes. Thicker pipes  may offer enhanced performance, but they can also be more expensive and consume more raw material. It is essential to analyze cost-effectiveness and evaluate the trade-offs between material usage, durability, and performance to make an informed decision.

may offer enhanced performance, but they can also be more expensive and consume more raw material. It is essential to analyze cost-effectiveness and evaluate the trade-offs between material usage, durability, and performance to make an informed decision.

Quality Control Measures

To ensure optimum quality and reliability, quality control measures play a crucial role in evaluating the thickness of cold rolled carbon steel pipes. Regular inspections, including non-destructive testing and visual examinations, allow manufacturers to identify any inconsistencies or defects in the thickness. These measures enable the production of pipes that meet the required standards and ensure a high level of performance in various applications.

Industry Standards and Specifications

Various international organizations and standards bodies have defined guidelines and specifications relating to the thickness of cold rolled carbon steel pipes. Adhering to these standards guarantees uniformity and consistency in the manufacturing and application of these pipes. Compliance with industry regulations ensures the pipes' suitability for specific environments and guarantees customer satisfaction.

Advanced Technologies and Innovations

Advancements in technology have led to innovative approaches in measuring and controlling the thickness of cold rolled carbon steel pipes. High-precision measurement tools and automated systems provide accurate and efficient means of ensuring dimensional integrity. These technologies improve productivity, reduce human error, and enhance the overall quality of the pipes.

4. Conclusion:

The thickness of cold rolled carbon steel pipes is a crucial element in their performance and durability. Understanding the influence of thickness on strength, thermal conductivity, and vibration absorption is essential for professionals in numerous industries. Considering factors such as manufacturing techniques, application requirements, and cost-effectiveness enables the selection of the appropriate thickness for specific applications. Embracing quality control measures, adhering to industry standards, and utilizing advanced technologies ensure the production and utilization of high-quality and reliable cold rolled carbon steel pipes. Continuous research and development in this area will further enhance the performance and range of applications for these pipes, promoting sustainable and efficient industrial practices.

Note: The above word count does not include the titles and subtitles.