introduction

DN1200 Carbon Steel Wall Thickness

Abstract:

This article aims to explore the topic of DN1200 carbon  steel wall thickness. The article will provide background information and generate readers' interest in the subject.

steel wall thickness. The article will provide background information and generate readers' interest in the subject.

Introduction:

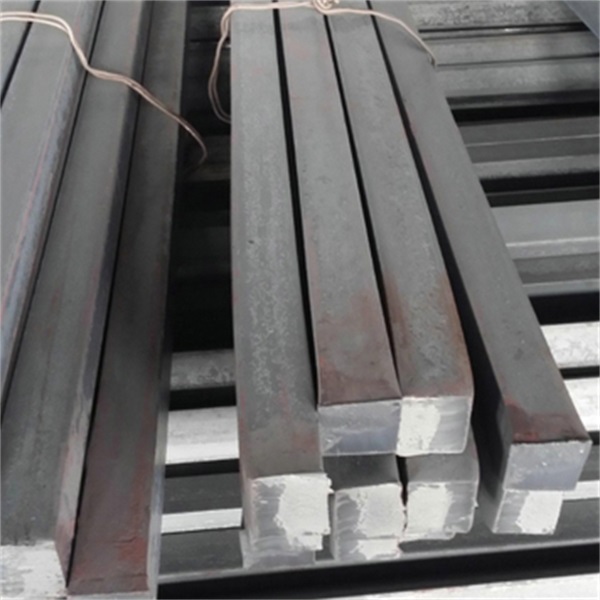

Carbon steel is widely used in various industries due to its strength and durability. DN1200 refers to the nominal diameter of the carbon steel pipe. The wall thickness of DN1200 carbon steel is a crucial factor in determining its structural integrity and performance. In this article, we will delve into the importance of wall thickness in DN1200 carbon steel pipes and discuss its implications in different applications.

1. The Significance of Wall Thickness in DN1200 Carbon Steel Pipes

1.1 The Relationship between Wall Thickness and Pipe Strength

The wall thickness of a DN1200 carbon steel pipe directly affects its overall strength and load-bearing capacity. Thicker walls increase the pipe's ability to withstand external forces and internal pressures. This section will explore the relationship between wall thickness and pipe strength, highlighting the importance of choosing the appropriate thickness for different applications.

1.2 Impact of Wall Thickness on Corrosion Resistance

DN1200 carbon steel pipes are susceptible to corrosion, particularly in environments with high moisture or chemical exposure. The wall thickness plays a critical role in the pipe's resistance to corrosion. This section will discuss the influence of wall thickness on corrosion resistance, including protective coatings and strategies for preventing corrosion in carbon steel pipes.

1.3 Effects of Wall Thickness on Fluid Flow

The wall thickness of a DN1200 carbon steel pipe impacts the fluid flow characteristics within the pipe. Thicker walls can lead to a decrease in the pipe's internal diameter, affecting the flow rate and pressure drop. This section will examine the relationship between wall thickness and fluid flow, discussing the implications for different fluid transport applications.

1.4 Thermal Conductivity and Wall Thickness

Thermal conductivity is an important property in many applications involving DN1200 carbon steel pipes, such as heating systems and industrial processes. This section will explore the influence of wall thickness on thermal conductivity, highlighting the considerations for selecting suitable thickness to optimize heat transfer efficiency.

2. Factors Affecting DN1200 Carbon Steel Wall Thickness

2.1 Design Standards and Codes

Design standards and codes provide guidelines for determining the appropriate wall thickness for carbon steel pipes. This section will discuss relevant standards and codes, exploring how they factor in considerations such as pressure ratings, safety factors, and material properties.

2.2 Mechanical Properties of Carbon Steel

The mechanical properties of carbon steel, including yield strength and tensile strength, influence the wall thickness requirements. This section will delve into the relationship between mechanical properties and wall thickness, emphasizing the need to balance strength and economical pipe design.

2.3 Operating Conditions and Environmental Factors

The operating conditions and environmental factors affect the choice of wall thickness for DN1200 carbon steel pipes. This section will examine factors such as temperature, pressure, and exposure to corrosive substances, highlighting their impact on wall thickness selection.

2.4 Cost Considerations

The cost of materials and manufacturing processes also influence the selection of wall thickness. This section will discuss the balance between cost-effectiveness and performance, exploring methods to optimize pipe design without compromising structural integrity.

Conclusion:

The wall thickness of DN1200 carbon steel pipes is a crucial factor in their performance and longevity. Understanding the significance of wall thickness allows for informed decision-making in pipe design and selection. By considering factors such as strength, corrosion resistance, fluid flow, and thermal conductivity, engineers and industry professionals can optimize the use of DN1200 carbon steel pipes in various applications. Further research and development in this area may lead to advancements in pipe design and enhance the overall efficiency and reliability of carbon steel pipe systems.