introduction

Identifying True and False Rebar Models: A Comprehensive Guide

Abstract:

This article aims to provide readers with an in-depth understanding of how to identify true and false rebar models. Rebar, a crucial material in construction, plays a vital role in ensuring the structural integrity and safety of buildings. However, the market is inundated with counterfeit rebar models, which pose a significant risk to construction projects. By considering four key aspects – physical characteristics, manufacturer information, certification, and testing – this article will equip readers with the necessary knowledge to differentiate between genuine and counterfeit rebar models.

Introduction:

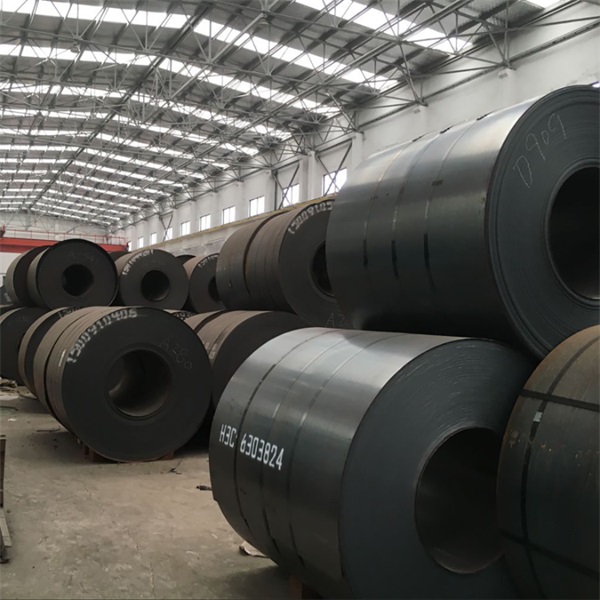

Rebar, short for reinforcing bar, is commonly used in construction to strengthen concrete structures. Its tensile strength and flexibility make it an indispensable component in the construction industry. However, the prevalence of counterfeit rebar models has become a pressing issue, jeopardizing the safety and durability of buildings. Identifying genuine rebar models from counterfeit ones is crucial to ensure the structural integrity of construction projects. This article will delve into the key factors to consider when distinguishing true and false rebar models.

1. Physical Characteristics

Rebar models can be distinguished based on their physical characteristics. Firstly, the diameter and rib pattern of the rebar should be examined. Genuine rebar models comply with standard measurements and exhibit uniform rib patterns throughout the entire length. Counterfeit rebar models often deviate from these standards, exhibiting inconsistencies in diameter and incomplete or irregular rib patterns. Additionally, the surface of genuine rebar models is free from rust, oil stains, or other defects, while counterfeit rebar may exhibit signs of poor quality manufacturing or improper handling during storage.

2. Manufacturer Information

Examining manufacturer information is crucial for identifying true and false rebar models. Genuine rebar models are accompanied by detailed manufacturer information, including the company name, address, and contact details. Moreover, legitimate manufacturers often provide QR codes or holographic labels on their products for easy verification. On the other hand, counterfeit rebar models may lack accurate manufacturer details or provide incomplete and inconsistent information. Therefore, it is essential to verify the manufacturer's credibility and ensure the provided information aligns with reputable sources.

3. Certification

Certification serves as a strong indicator of the authenticity of rebar models. Genuine rebar models adhere to relevant industry standards,  such as ISO 9001 certification, ensuring compliance with quality management systems. Authentic manufacturers obtain certification from recognized accreditation bodies, which can be verified through their websites or official databases. Conversely, counterfeit rebar models often lack proper certification or offer counterfeit certificates that are difficult to validate. It is crucial to cross-reference certification information with official databases to confirm its legitimacy.

such as ISO 9001 certification, ensuring compliance with quality management systems. Authentic manufacturers obtain certification from recognized accreditation bodies, which can be verified through their websites or official databases. Conversely, counterfeit rebar models often lack proper certification or offer counterfeit certificates that are difficult to validate. It is crucial to cross-reference certification information with official databases to confirm its legitimacy.

4. Testing

Performing proper testing is indispensable in distinguishing true and false rebar models. Non-destructive testing (NDT) methods, such as ultrasonic testing and magnetic particle inspection, can identify structural defects or inconsistencies in rebar models. Genuine rebar models are subjected to rigorous testing procedures to ensure their quality and adherence to safety standards. Conversely, counterfeit rebar models may lack the necessary testing documentation or exhibit defects that compromise structural integrity. Collaborating with certified testing laboratories can provide comprehensive analysis and validation of rebar models.

Conclusion:

In conclusion, identifying true and false rebar models is crucial for maintaining safety and integrity in the construction industry. By considering four key aspects – physical characteristics, manufacturer information, certification, and testing – one can differentiate between genuine and counterfeit rebar models. Physical examination, verification of manufacturer details, validation of certification, and rigorous testing are the necessary steps to ensure the quality and reliability of rebar models. By employing these strategies, construction professionals and stakeholders can safeguard their projects and ensure the longevity of their structures.