introduction

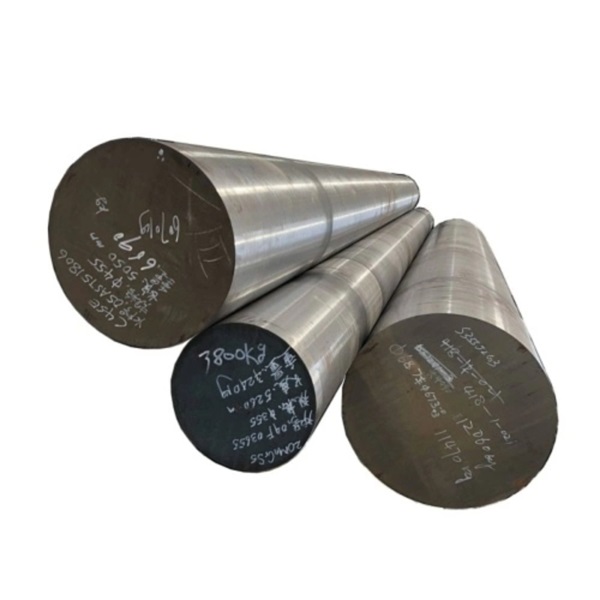

Carbon steel, a widely used material in various industries, is known for its strength and durability. However, it is also recognized for its poor purity, which can have significant implications on its performance and properties. In this article, we will delve into the topic of carbon steel's poor purity, exploring its causes, effects, and potential solutions. By understanding this aspect of carbon steel, we can gain valuable insights into how to optimize its use and enhance its overall efficiency.

1. The Origin of Poor Purity

Carbon steel's poor purity originates from several factors, ranging from production processes to material composition. Firstly, during the manufacturing process, impurities can be introduced due to inadequate refining techniques or insufficient attention to quality control. This can result in the presence of elements such as sulfur, phosphorus, and oxygen, which degrade the steel's purity. Secondly, the raw materials used in carbon steel production, including iron ore and coal, can also contain  impurities that persist throughout the manufacturing process. These impurities, if not properly managed, can negatively impact the steel's overall purity.

impurities that persist throughout the manufacturing process. These impurities, if not properly managed, can negatively impact the steel's overall purity.

2. Effects on Mechanical Properties

The presence of impurities in carbon steel has a direct impact on its mechanical properties. One prominent effect is the reduction in strength and ductility. Impurities can act as stress concentration points, leading to localized weak spots and increased susceptibility to fracture. Furthermore, impurity-induced segregations can result in uneven distribution of solute atoms, altering the steel's microstructure and further compromising its mechanical properties. This can ultimately lead to decreased load-bearing capacity and reduced service life of carbon steel components.

3. Influences on Corrosion Resistance

Another critical aspect affected by carbon steel's poor purity is its corrosion resistance. Impurities such as sulfur and phosphorus can promote the formation of corrosive compounds, accelerating the corrosion process. In addition, oxygen present in the steel can initiate oxidation reactions, leading to the formation of rust and subsequent corrosion. Consequently, carbon steel with high impurity levels may exhibit a shorter lifespan in corrosive environments, making it unsuitable for certain applications.

4. Mitigation and Future Directions

Efforts to mitigate the issue of carbon steel's poor purity are ongoing in both industrial and scientific communities. One common approach is through advanced refining techniques, such as vacuum degassing and ladle refining, which aim to remove impurities during the steelmaking process. Furthermore, developments in material characterization and analysis methods allow for better understanding and control of impurity levels. This knowledge can guide the optimization of manufacturing processes and raw material selection, leading to the production of purer carbon steel with improved performance.

In conclusion, carbon steel's poor purity is a significant aspect that requires attention in various industries. The presence of impurities can have detrimental effects on the mechanical properties and corrosion resistance of carbon steel. However, through continuous research and development, including advancements in refining techniques and material analysis, it is possible to mitigate this issue and optimize the performance of carbon steel. By understanding the causes and effects of poor purity, we can work towards the production of purer and more efficient carbon steel, enhancing its overall value and lifespan.