introduction

Carbon steel, apart from iron, contains carbon as the main element. Carbon steel is a widely used material in various industries due to its strength, durability, and versatility. In this article, we will delve into the properties, types, applications, and manufacturing processes of carbon steel. By exploring these aspects, we aim to provide readers with a comprehensive understanding of carbon steel and its significance in the modern world.

1. Properties of Carbon Steel

Carbon steel possesses unique properties that make it highly suitable for a wide range of applications. With varying carbon content, carbon steel can exhibit different characteristics, including strength, hardness, ductility, and machinability. The carbon content directly affects the material's hardness and strength, while other alloy elements contribute to its corrosion resistance and other specific properties. Understanding the properties of carbon steel is crucial in selecting the right grade for a particular application.

2. Types of Carbon Steel

Carbon steel can be classified into several types based on its carbon content and the presence of other alloying elements. Low carbon steel, also known as mild steel, contains a small amount of carbon, making it easier to weld and form. Medium carbon steel has a higher carbon content, providing increased strength and hardness. High carbon steel, with the highest carbon content, offers exceptional strength but is less ductile. Additionally, carbon steel alloys such as stainless steel and tool steel have specific properties suitable for specialized applications.

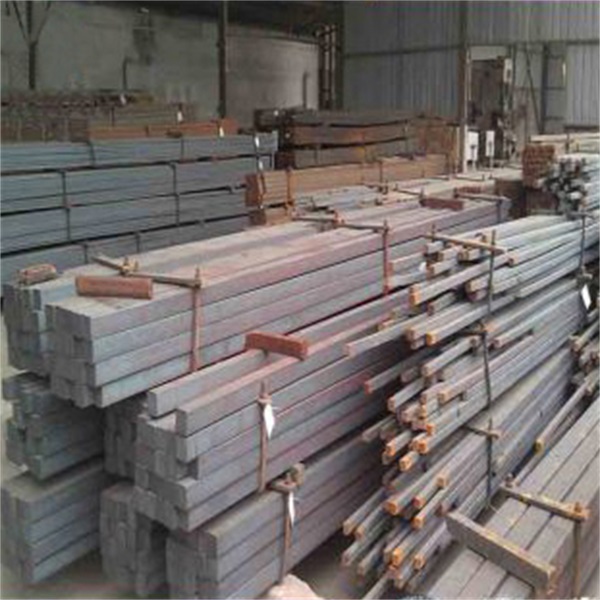

3. Applications of Carbon Steel

The versatility  and strength of carbon steel make it a widely used material in various industries. Construction and infrastructure rely heavily on carbon steel for structural components, including beams, columns, and reinforcement bars. Automotive and transportation industries utilize carbon steel for manufacturing vehicles and parts due to its strength and impact resistance. Carbon steel is also prevalent in the energy sector for oil and gas pipelines, as well as in manufacturing machinery, appliances, and consumer goods.

and strength of carbon steel make it a widely used material in various industries. Construction and infrastructure rely heavily on carbon steel for structural components, including beams, columns, and reinforcement bars. Automotive and transportation industries utilize carbon steel for manufacturing vehicles and parts due to its strength and impact resistance. Carbon steel is also prevalent in the energy sector for oil and gas pipelines, as well as in manufacturing machinery, appliances, and consumer goods.

4. Manufacturing Processes of Carbon Steel

The manufacturing of carbon steel involves several processes, each contributing to the final properties of the material. The primary method is steelmaking, which includes the conversion of iron ore into iron and the subsequent addition of carbon and other alloying elements. Steelmaking can be achieved through various techniques such as the Basic Oxygen Furnace (BOF) and Electric Arc Furnace (EAF). After steelmaking, the steel is then shaped into the desired form through processes like hot rolling, cold rolling, forging, and casting.

In conclusion, carbon steel, apart from iron, is a versatile and widely used material with numerous applications. Its diverse properties, types, and manufacturing processes make it suitable for various industries, from construction to transportation. Understanding carbon steel allows for informed material selection and ensures the optimal performance of products and structures. Further research and development in carbon steel technology can lead to advancements in material science and engineering, contributing to the overall progress of society.

References:

1. Smith, William F. "Carbon and alloy steels." The Encyclopedia of Materials Science and Technology (2011): 201-206.

2. Jenkins, Brent. "Carbon steel." ASM International (2009).

3. Dieter, George E. Mechanical metallurgy. McGraw-Hill Education, 1988.