introduction

Carbon Steel Splicing: A Comprehensive Guide

Abstract:

This article aims to provide a comprehensive guide to carbon steel splicing, a crucial process in various industries such as construction, manufacturing, and engineering. By examining the different aspects of carbon steel splicing, readers will gain a deeper understanding of its importance, applications, and techniques. The article will also explore the advancements and challenges in this field, offering valuable insights and suggestions for further research.

1. The Fundamentals of Carbon Steel Splicing

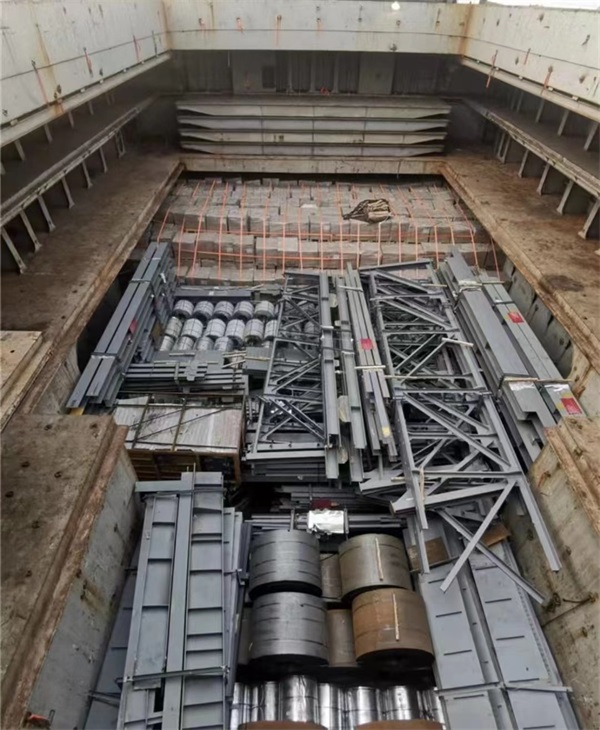

Carbon steel splicing plays a vital role in joining two or more pieces of carbon steel together. This technique is widely used in structural applications, including the construction of buildings, bridges, pipelines, and machinery. The first aspect of this article will delve into the fundamental principles of carbon steel splicing, highlighting its significance in creating robust, durable connections.

Carbon steel splicing involves the use of various methods, such as welding, mechanical fasteners, adhesives, and brazing. Each method has its advantages and limitations, and this section will explore these in detail. Welding, for instance, is a popular technique that offers high strength and ensures continuity in the structural integrity of the spliced joint. Mechanical fasteners, on the other hand, provide ease of installation and disassembly, making them suitable for applications requiring frequent maintenance or modifications.

Furthermore, this section will discuss the factors that influence the choice of splicing method, including the type and thickness of the carbon steel, the load-bearing requirements, environmental conditions, and cost considerations. By understanding these factors, engineers and designers can make informed decisions when selecting the most appropriate splicing technique for their projects.

2. Advanced Techniques and Innovations in Carbon Steel Splicing

With the advancement of technology, new techniques and innovations have emerged in the field of carbon steel splicing. This section will explore the latest developments in this area, shedding light on cutting-edge methodologies and their potential applications.

One such innovation is the use of laser welding in carbon steel splicing. Laser welding offers numerous benefits, including precise control over the heat affected zone, minimal distortion, and higher welding speeds. This subsection will delve into the principles and applications of laser welding, showcasing its advantages in joining carbon steel components with exceptional accuracy and strength.

Moreover, advancements in adhesive bonding techniques have revolutionized carbon steel splicing, particularly in industries where traditional welding may not be feasible. Structural adhesives, such as epoxy and polyurethane adhesives, provide a strong bond while maintaining the structural integrity of the joined components. This portion will discuss the properties, application methods, and considerations associated with adhesive bonding in carbon steel splicing.

Additionally, this section will highlight other innovative techniques, including friction stir welding, electron beam welding, and ultrasonic welding, each offering unique advantages in specific applications. By exploring these advanced techniques, this article aims to inspire further research and innovation in the field of carbon steel splicing.

3. Challenges and Future Directions in Carbon Steel Splicing

While carbon steel splicing has made significant progress, this section will address the challenges and limitations that researchers and practitioners face in this field. By acknowledging these challenges, it is possible to identify areas for improvement and future research focus.

One of the primary challenges in carbon steel splicing is the potential for weld defects, such as porosity, cracks, and distortion. This subsection will discuss the causes of these defects and explore techniques and approaches to mitigate their occurrence. Moreover, the increasing demand for lightweight and high-strength carbon steel poses challenges for splicing methods, as they must adapt to thinner and more complex structures. This section will explore the impact of these challenges and potential solutions, such as advanced welding processes and novel joint designs.

Furthermore, environmental concerns and regulations necessitate the development of sustainable splicing techniques. This part of the article will address the importance of reducing carbon emissions, minimizing waste generation, and adopting environmentally friendly practices in carbon steel splicing. It will explore eco-friendly alternatives to traditional splicing methods and discuss the potential for incorporating recyclable materials in the joining process.

4. Conclusion

In conclusion, carbon steel splicing is a critical process in various industries, enabling the creation of robust, durable connections in structural  applications. This comprehensive guide has explored the fundamentals, advancements, challenges, and future directions in carbon steel splicing. By understanding the principles, techniques, and innovations associated with this process, engineers and researchers can make informed decisions, overcome obstacles, and contribute to the continuous improvement of carbon steel splicing.

applications. This comprehensive guide has explored the fundamentals, advancements, challenges, and future directions in carbon steel splicing. By understanding the principles, techniques, and innovations associated with this process, engineers and researchers can make informed decisions, overcome obstacles, and contribute to the continuous improvement of carbon steel splicing.