introduction

Classification and Use of Carbon Steel

Abstract:

This article aims to provide an in-depth understanding of the classification and use of carbon steel. It begins by introducing the topic and highlighting its relevance. Carbon steel is one of the most widely used materials in various industries due to its excellent properties. Understanding its classification and use is crucial for engineers, manufacturers, and professionals working with metals. The article delves into four main aspects: classification based on carbon content, use in construction and infrastructure, applications in the automotive industry, and its importance in manufacturing and fabrication processes. By analyzing each aspect, this article aims to provide readers with comprehensive knowledge of carbon steel and its various uses.

1. Classification based on carbon content

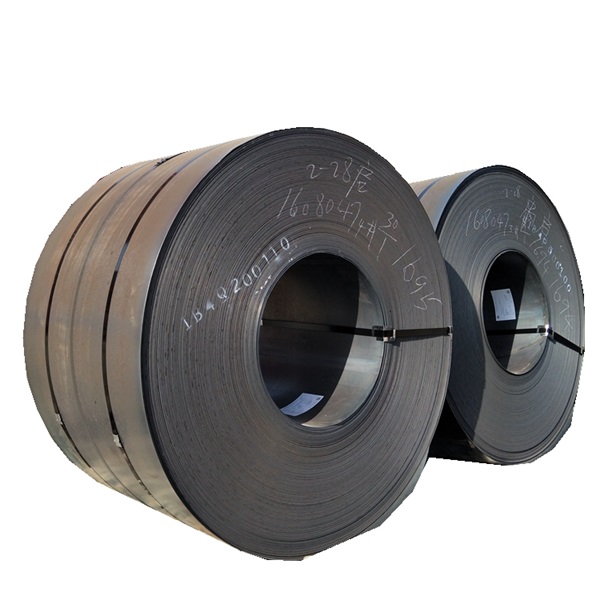

Carbon steel is classified into various categories based on its carbon content. These categories include low carbon steel, medium carbon steel, and high carbon steel. Each type has its unique properties and applications. Low carbon steel, for example, is known for its ductility and malleability, making it suitable for applications such as construction and manufacturing. Medium carbon steel, on the other hand, offers a balance between strength and ductility and is commonly used in machinery and automotive parts. High carbon steel is known for its excellent hardness and is often used in tools and blades.

2. Use in construction and infrastructure

Carbon steel plays a crucial role in the construction and infrastructure industry. Its strength, durability, and cost-effectiveness make it a preferred choice for structural components such as beams, columns, and reinforcing bars. Carbon steel is also used in the construction of bridges, pipelines, and storage tanks due to its high resistance to corrosion. Its versatility allows for custom fabrication, giving architects and engineers the freedom  to design structures of various shapes and sizes. Additionally, carbon steel's recyclability makes it an environmentally friendly choice.

to design structures of various shapes and sizes. Additionally, carbon steel's recyclability makes it an environmentally friendly choice.

3. Applications in the automotive industry

The automotive industry heavily relies on carbon steel for various components and structures. Carbon steel is widely used in the manufacturing of car bodies, chassis, and suspension systems. Its high strength-to-weight ratio makes vehicles lighter and more fuel-efficient without compromising safety. Additionally, carbon steel's formability allows for complex designs and shapes, enhancing the aesthetics of automobiles. Furthermore, carbon steel's high impact resistance and toughness contribute to the safety aspects of vehicles, providing protection in the event of collisions.

4. Importance in manufacturing and fabrication processes

Carbon steel is a vital material in the manufacturing and fabrication processes. Its versatility and ease of fabrication make it an excellent choice for a wide range of applications. From machining and welding to forming and cutting, carbon steel can be readily processed using various techniques. Its compatibility with different types of coatings and finishes allows for the production of aesthetically appealing and functional products. The use of carbon steel in manufacturing and fabrication contributes to overall productivity and cost-effectiveness.

Conclusion:

In conclusion, carbon steel's classification and use are crucial to various industries. Understanding the different types of carbon steel and their applications allows for informed material selection and optimization of performance. Whether in construction, automotive, or manufacturing, carbon steel offers numerous advantages such as strength, durability, and versatility. By utilizing carbon steel effectively, engineers, manufacturers, and professionals can create innovative and sustainable solutions. Further research and development in carbon steel technology can lead to even more advancements and applications in the future.