introduction

American Standard for Cold Rolled Mild Steel

Abstract:

This article aims to provide an in-depth understanding of the American Standard for Cold Rolled Mild Steel. It discusses the background of this standard and its significance in various industries. By exploring four main aspects, namely chemical composition, mechanical properties, dimensional accuracy, and surface finish, this article seeks to provide readers with a comprehensive overview of the American Standard for Cold Rolled Mild Steel.

1. Chemical Composition:

The chemical composition of cold rolled mild steel plays a crucial role in determining its properties and applications.Chemical Composition

Mild steel typically consists of a low carbon content, ranging from 0.05% to 0.25%. This low carbon content ensures good weldability and formability, making it suitable for various manufacturing processes. Additionally, the presence of elements such as manganese, phosphorus, sulfur, and silicon affects the material's strength, ductility, and corrosion resistance.

resistance. 1. Influence of Carbon Content

The carbon content in cold rolled mild steel directly affects its hardness and tensile strength. Higher carbon levels result in increased hardness but decreased ductility.2. Effect of Alloying Elements

Alloying elements such as manganese and silicon contribute to the formation of solid solutions that enhance the material's strength and toughness. Phosphorus and sulfur, on the other hand, can have detrimental effects on the steel's mechanical properties.3. Importance of Chemical Analysis

Accurate chemical analysis is vital in ensuring the quality and consistency of cold rolled mild steel. It assists in verifying compliance with the American Standard, enabling manufacturers to produce reliable and predictable materials.

2. Mechanical Properties:

Understanding the mechanical properties of cold rolled mild steel is crucial for selecting appropriate materials in various applications.Mechanical Properties

The mechanical properties of cold rolled mild steel, such as tensile strength, yield strength, and elongation, determine its suitability for different engineering purposes.1. Tensile Strength and Yield Strength

Tensile strength refers to the maximum stress a material can withstand before fracturing, while yield strength represents the stress at which permanent deformation occurs. These properties are important indicators of the material's strength and structural integrity.2. Ductility and Elongation

Ductility is the ability of a material to undergo plastic deformation without breaking. Elongation measures the percentage increase in length of the material during tensile testing. These properties influence the material's malleability and formability.3. Impact Resistance and Hardness

Cold rolled mild steel is known for its excellent impact resistance and moderate hardness. These properties make it suitable for applications requiring toughness and resistance to deformation.

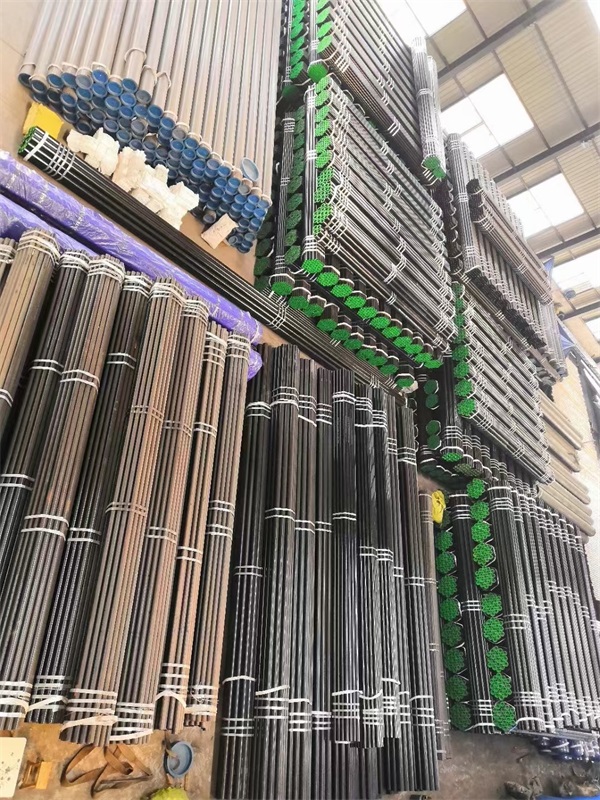

3. Dimensional Accuracy:

Dimensional accuracy is a critical aspect of cold rolled mild steel, ensuring compatibility and interchangeability in various engineering projects.Dimensional Accuracy

The American Standard for Cold Rolled Mild Steel provides specific guidelines for dimensional tolerances to ensure adherence to required measurements.1. Thickness and Width Tolerances

The standard specifies the acceptable range of thickness and width deviations, ensuring uniformity and consistency in sheet and strip products.2. Length and Straightness Tolerances

Length and straightness tolerances are crucial for ensuring the compatibility of cold rolled mild steel in construction and fabrication projects. Any deviations from the standard can affect the overall quality and performance of the materials.3. Surface Flatness

The American Standard also addresses the surface flatness requirements of cold rolled mild steel, ensuring optimal contact and fitment in various applications.

4. Surface Finish:

The surface finish of cold rolled mild steel plays a vital role in its appearance, corrosion resistance, and paint adhesion.Surface Finish

The American Standard specifies various surface finishes for cold rolled mild steel, ensuring specific requirements are met for different applications.1. Mill Finish

Mill finish is the most basic surface finish, characterized by a rough texture directly from the cold rolling process.2. Pickled Finish

Pickled finish involves the removal of mill scale through the use of acids, resulting in a clean and smooth surface.3. Bright Finish

Bright finish is achieved through additional processing, such as annealing, to enhance the material's appearance and corrosion resistance. This finish is commonly used in architectural and decorative applications.

Conclusion:

The American Standard for Cold Rolled Mild Steel plays a pivotal role in ensuring the quality, consistency, and performance of this versatile material. Understanding the chemical composition, mechanical properties, dimensional accuracy, and surface finish is essential for selecting and utilizing cold rolled mild steel effectively. By adhering to this standard, manufacturers can produce reliable products that meet the diverse requirements of various industries. Continuous research and development in this field will further enhance the understanding and application of the American Standard for Cold Rolled Mild Steel.