introduction

Are Seamed Steel Pipes Carbon Steel Pipes?

Abstract:

In the world of steel pipes, there has often been confusion surrounding the distinction between seamed steel pipes and carbon steel pipes. This article aims to shed light on this topic by providing a comprehensive analysis of the two types of pipes. By discussing their characteristics, manufacturing processes, and applications, readers will gain a deeper understanding of the differences and similarities between these pipe types.

Text:

1. Characteristics of Seamed Steel Pipes

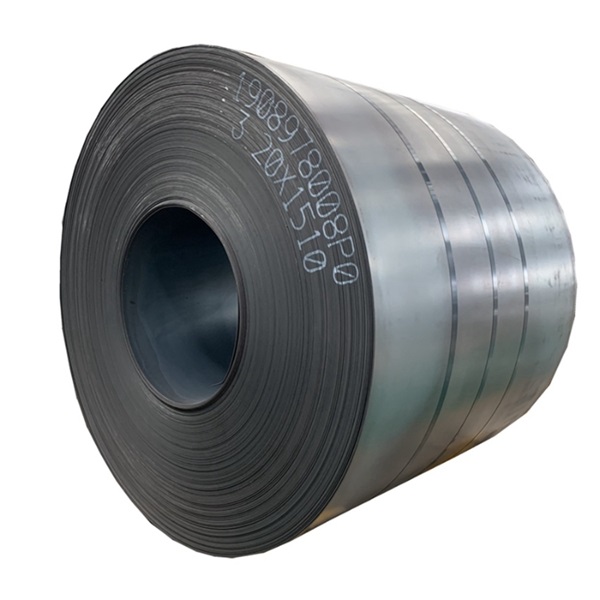

Seamed steel pipes, also known as welded pipes, are manufactured by bending and welding a flat steel strip into a cylindrical shape. One of the key  characteristics of seamed steel pipes is their visible seam, which results from the welding process. These pipes are available in various sizes and can be produced with different thicknesses to suit different applications.

characteristics of seamed steel pipes is their visible seam, which results from the welding process. These pipes are available in various sizes and can be produced with different thicknesses to suit different applications.

Seamed steel pipes can be further classified into different types based on the welding method used. These include longitudinal, spiral, and submerged arc welded pipes. Longitudinal seamed pipes are created by welding along the length of the pipe, while spiral seamed pipes are formed by helically welding a continuous steel strip. Submerged arc welded pipes are manufactured by submerging the welded joint in flux to protect it from contamination during the welding process.

2. Characteristics of Carbon Steel Pipes

Carbon steel pipes, on the other hand, refer to pipes made primarily from carbon steel, a widely used material in various industries. Carbon steel is an alloy composed of iron and carbon, and it is known for its strength, durability, and resistance to corrosion. These pipes are available in a wide range of sizes, thicknesses, and grades to suit different applications.

One of the notable characteristics of carbon steel pipes is their high tensile strength, which makes them suitable for transporting fluids and gases under high pressure. They are also known for their excellent thermal conductivity and low thermal expansion, making them ideal for conveying hot and cold fluids.

3. Manufacturing Processes of Seamed Steel Pipes and Carbon Steel Pipes

Seamed steel pipes are manufactured through a series of processes that involve the shaping and welding of the steel strip. The strip is first formed into a cylindrical shape using either a bending machine or a roll-forming mill. The edges of the strip are then brought together and welded to create a continuous seam. This welding process can be done using various techniques such as electric resistance welding, high-frequency induction welding, or submerged arc welding.

Carbon steel pipes, on the other hand, are manufactured through a process called seamless pipe manufacturing. This involves the formation of a solid cylindrical billet by either hot extrusion or piercing a solid round ingot. The billet is then heated and stretched to reduce its diameter and wall thickness. This process is repeated multiple times until the desired pipe size is achieved. The resulting pipe has no seam and is known for its uniformity and strength.

4. Applications of Seamed Steel Pipes and Carbon Steel Pipes

Seamed steel pipes find applications in various industries such as oil and gas, construction, and automotive. They are commonly used for transporting liquids and gases, structural purposes, and as casing and tubing in oil and gas wells. The visible seam in seamed steel pipes does not affect their performance and they are a cost-effective choice for many applications.

Carbon steel pipes, on the other hand, have a wide range of applications due to their versatile properties. They are extensively used in industries such as oil and gas, petrochemical, power generation, and construction. These pipes are commonly used for transporting oil, gas, water, and steam. Carbon steel pipes are also utilized in structural applications, such as in the construction of bridges, buildings, and infrastructure.

Conclusion:

In conclusion, seamed steel pipes and carbon steel pipes are distinct types of pipes with their own characteristics and manufacturing processes. Seamed steel pipes are manufactured through welding processes and are known for their visible seam. They find applications in various industries, especially where cost-effectiveness is important. Carbon steel pipes, on the other hand, are made primarily from carbon steel and have no seam. They are widely used in many industries due to their strength, durability, and versatility. Understanding the differences and similarities between these pipe types is crucial for making informed decisions in various applications.