introduction

Abstract:

The thermal conductivity of cold drawn low carbon steel wire is a crucial characteristic that affects its performance in various applications. This article aims to provide a comprehensive understanding of this property and its significance. By exploring the factors that influence thermal conductivity, the effects of cold drawing on low carbon steel wire, the applications of this material, and the methods used to measure its thermal conductivity, readers will gain insights into its potential uses and limitations. This research is essential for industries such as automotive, construction, and electronics, where thermal management is critical for efficient operations.

1. Factors Influencing Thermal Conductivity

Thermal conductivity is influenced by various factors, including the chemical composition of the steel wire, impurities, crystal lattice structure, temperature, and grain boundaries. Each of these factors plays a significant role in determining the overall thermal conductivity of the material. Understanding these factors is essential for optimizing the thermal conductivity of low carbon steel wire in applications where heat transfer is vital.

2. Effects of Cold Drawing on Low Carbon Steel Wire

Cold drawing is a processing method that enhances the mechanical properties of low carbon steel wire. However, this process also affects the thermal conductivity of the material. As the wire undergoes cold drawing, its microstructure changes, leading to alterations in its thermal conductivity. It is crucial to investigate the relationship between cold drawing parameters and thermal conductivity to ensure the use of low carbon steel wire in applications where heat dissipation is a primary concern.

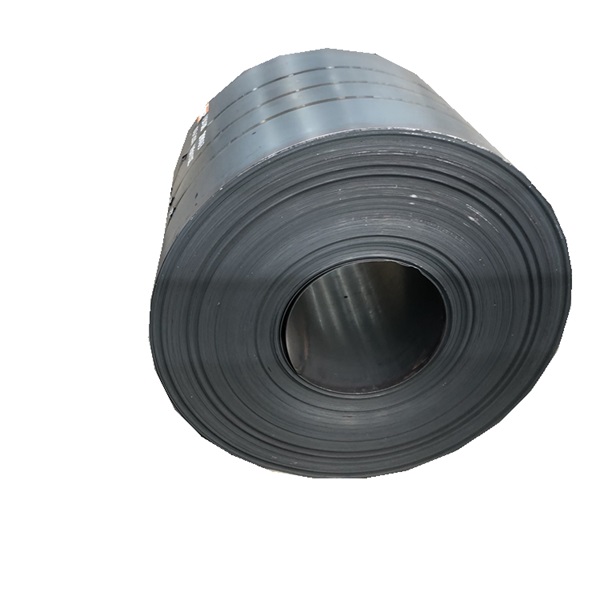

3. Applications of Cold Drawn Low Carbon Steel Wire

Cold drawn low carbon steel wire finds applications  in various sectors, including automotive, construction, and electronics industries. Its excellent mechanical properties coupled with adequate thermal conductivity make it suitable for manufacturing components such as springs, fasteners, reinforcement materials, and electrical connectors. Understanding the thermal conductivity of this material is crucial for designing efficient and reliable systems.

in various sectors, including automotive, construction, and electronics industries. Its excellent mechanical properties coupled with adequate thermal conductivity make it suitable for manufacturing components such as springs, fasteners, reinforcement materials, and electrical connectors. Understanding the thermal conductivity of this material is crucial for designing efficient and reliable systems.

4. Methods Used to Measure Thermal Conductivity

Several methods can be employed to measure the thermal conductivity of cold drawn low carbon steel wire. These include the steady-state method, transient methods, and laser flash analysis. Each method has its advantages and limitations, and the selection of an appropriate method depends on the specific requirements of the study. Accurate measurement techniques are necessary to ensure reliable data and enable further research and development in this field.

Conclusion:

In conclusion, the thermal conductivity of cold drawn low carbon steel wire is a vital property that influences its performance in various applications. By understanding the factors that affect thermal conductivity, the effects of cold drawing, as well as its applications and measurement methods, researchers and engineers can optimize the use of this material for efficient heat transfer and thermal management. Further studies should focus on exploring novel approaches to enhance the thermal conductivity of low carbon steel wire while maintaining its mechanical properties. This research will contribute to the development of high-performance materials for diverse industries, leading to more energy-efficient and reliable systems.