introduction

Inspection and Testing Standards for Precision Rolled Rebar

Abstract:

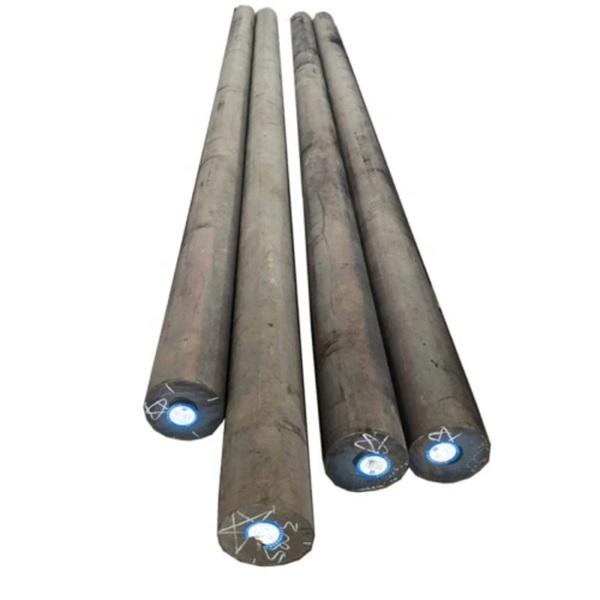

This article introduces the inspection and testing standards for precision rolled rebar, aiming to provide readers with a thorough understanding of the subject. Precision rolled rebar plays a crucial role in the construction industry, and ensuring its quality and compliance with standards is essential. By exploring the inspection and testing standards in detail, this article aims to enhance readers' knowledge and promote the use of high-quality precision rolled rebar in construction projects.

Introduction:

The construction industry heavily relies on precision rolled rebar for various applications, such as reinforcement in concrete structures. The quality of these rebar products directly impacts the safety and durability of buildings and infrastructure. Therefore, it is vital to have strict inspection and testing standards in place to ensure the reliability of precision rolled rebar. In this article, we will delve into the details of these standards, their significance, and the procedures involved.

1. Steel Grade and Chemical Composition:

1.1 Definition and Significance of Steel Grade:

1. Steel Grade and Chemical Composition

Steel grade refers to the specific composition and mechanical properties of the steel used in precision rolled rebar. Different steel grades are suitable for various applications and have varying levels of strength, ductility, and corrosion resistance. It is crucial to select the  appropriate steel grade to ensure the rebar's performance meets the project requirements.

appropriate steel grade to ensure the rebar's performance meets the project requirements.

1.2 Chemical Composition Testing:

To determine the chemical composition of precision rolled rebar accurately, various testing methods are employed. The elemental composition is analyzed using techniques such as spectrometry or energy-dispersive X-ray spectroscopy. This testing verifies whether the chemical composition of the rebar aligns with the specified standards for the given steel grade.

1.3 Acceptance Criteria:

The acceptance criteria for the chemical composition of precision rolled rebar are based on industry and national standards. Deviations from the specified composition should not exceed certain limits to ensure the rebar's structural integrity and performance.

2. Mechanical Properties:

2.1 Mechanical Testing Methods:

2. Mechanical Properties

Testing the mechanical properties of precision rolled rebar is crucial to ensure its strength, elongation, and other desired characteristics. Various testing methods such as tensile testing, bend testing, and impact testing are employed to evaluate these properties effectively.

2.2 Tensile Strength:

Tensile strength determines the maximum stress a rebar can withstand before failure. This property is critical as it influences the rebar's load-bearing capacity and its ability to resist deformation under tension.

2.3 Yield Strength and Elongation:

Yield strength is the stress at which a rebar starts to exhibit plastic deformation. It is a vital parameter for structural design and construction. Elongation measures the rebar's ability to stretch before fracturing, indicating its ductility. These properties directly influence the rebar's performance and structural safety.

3. Dimensional Characteristics:

3.1 Diameter and Length Measurement:

3. Dimensional Characteristics

Precision in rebar dimensions is crucial to ensure proper fit and structural integrity. The diameter and length of the rebar are measured using precision instruments such as calipers or laser-based measuring devices. These measurements need to be within specified tolerances for the rebar to be considered acceptable.

3.2 Rib Design and Dimensions:

The presence of ribs on the surface of precision rolled rebar enhances its bond strength with concrete. It is essential to inspect and measure the ribs' dimensions, such as height, spacing, and angle, to ensure that they comply with the standards and contribute to the desired mechanical characteristics of the rebar-concrete composite.

4. Corrosion Resistance:

4.1 Corrosion Testing Methods:

4. Corrosion Resistance

Corrosion significantly compromises the durability and structural performance of rebar. To assess corrosion resistance, various methods such as salt spray testing, potentiostatic testing, or electrochemical impedance spectroscopy are employed.

4.2 Coating Inspection:

If precision rolled rebar is coated with corrosion-resistant materials such as epoxy or zinc, the quality of the coating needs to be inspected. Coating thickness, adhesion, and overall quality are critical factors in determining its effectiveness in protecting the rebar from corrosion.

Conclusion:

In conclusion, inspection and testing standards for precision rolled rebar are integral to ensure the quality, reliability, and structural integrity of construction projects. By adhering to these standards, the construction industry can minimize failures, enhance safety, and increase the longevity of structures. The examination of steel grade and chemical composition, mechanical properties, dimensional characteristics, and corrosion resistance enables stakeholders to make informed decisions and select high-quality precision rolled rebar for their projects. Continued research and development in this field will further advance these standards and contribute to the overall improvement of the construction industry.