introduction

Abstract:

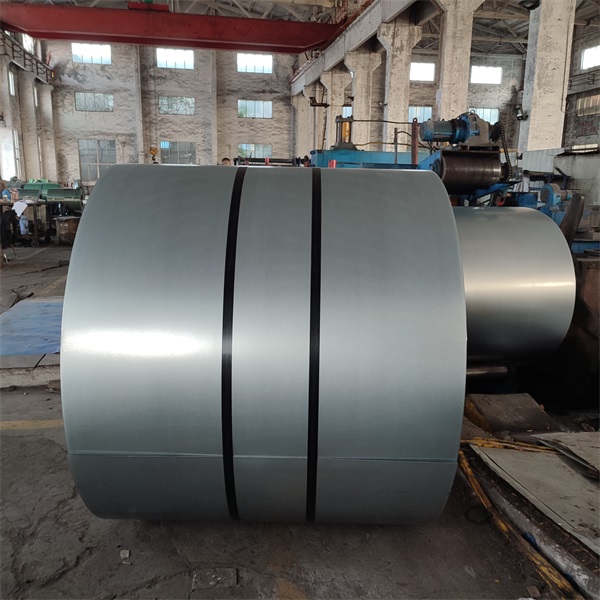

In this article, we explore the fascinating world of cold extruded carbon steel. We provide background information and aim to captivate readers' interest in this subject. Cold extrusion is a manufacturing process that involves shaping metal by applying pressure in a cold state, rather than heating it. Carbon steel, with its exceptional strength and durability, becomes an ideal material for cold extrusion. This article delves into the various aspects of cold extruded carbon steel, highlighting its properties, applications, manufacturing techniques, and future prospects.

1. Properties of Cold Extruded Carbon Steel

Cold extruded carbon steel possesses unique properties that make it highly desirable in numerous industries. The process enhances its strength, hardness, and dimensional stability. With superior tensile and yield strengths, cold extruded carbon steel exhibits excellent resistance to wear, corrosion, and fatigue. These properties make it suitable for applications in automotive, aerospace, construction, and machinery  industries. The exceptional properties of this material contribute to its widespread adoption and use.

industries. The exceptional properties of this material contribute to its widespread adoption and use.

2. Applications of Cold Extruded Carbon Steel

The versatility of cold extruded carbon steel enables its application in various industries. From automotive components like gears and shafts to precision tools and machinery parts, this material plays a vital role in ensuring the efficiency and reliability of many systems. Its exceptional strength and durability make it particularly suitable for applications that require high load-bearing capabilities. Additionally, the corrosion resistance of cold extruded carbon steel allows it to withstand harsh environments, further expanding its usability.

3. Manufacturing Techniques of Cold Extruded Carbon Steel

The manufacturing process of cold extruded carbon steel involves multiple steps that contribute to its unique properties. Starting with the selection of the appropriate carbon steel grade, the material undergoes a series of cold shaping processes. These processes include tooling design, billet preparation, lubrication, extrusion, and heat treatment. Each step plays a crucial role in determining the final properties of the material. Careful control and optimization of these manufacturing techniques are essential to ensure consistent and high-quality cold extruded carbon steel.

4. Future Prospects and Advancements in Cold Extruded Carbon Steel

The field of cold extruded carbon steel is continuously evolving with advancements in manufacturing techniques and material science. Ongoing research focuses on further enhancing the properties of cold extruded carbon steel, such as increasing its formability and ductility. Additionally, efforts are being made to explore new alloy compositions and optimize the extrusion process for better performance. The future holds promising developments in this field, with cold extruded carbon steel playing a vital role in meeting the increasing demands of various industries.

Conclusion:

In conclusion, cold extruded carbon steel offers exceptional properties that make it highly advantageous in numerous industries. Its strength, durability, corrosion resistance, and dimensional stability contribute to its widespread application and use. The manufacturing techniques used in producing cold extruded carbon steel play a pivotal role in determining its final properties. Ongoing advancements in this field are set to further optimize the material's properties and open up new possibilities for its application. Cold extruded carbon steel is an essential material in shaping the future of various industries, and its importance will only continue to grow.