introduction

LY Steel Rebar Defective Products: A Comprehensive Analysis

Abstract:

This article focuses on the issue of LY Steel Rebar Defective Products, providing readers with an in-depth analysis of the situation. It aims to shed light on the background information related to this topic and generate readers' interest.

Text:

1. Overview of LY Steel Rebar Defective Products

LY Steel, a prominent player in the steel industry, has faced significant challenges due to the quality issues in its rebar products. These defects have posed serious concerns for construction projects and have drawn attention from various stakeholders. Understanding the extent and impact of these defective products is crucial for addressing the issue effectively.

The evolution of the LY Steel Rebar Defective Products issue can be traced back to the discovery of substandard rebar in several high-profile construction projects. These incidents have raised questions about the quality control measures implemented by LY Steel. It is essential to delve into the reasons behind the defects and examine the consequences they have had on the construction industry.

2. Causes of LY Steel Rebar Defective Products

a. Quality Control Procedures and Standards

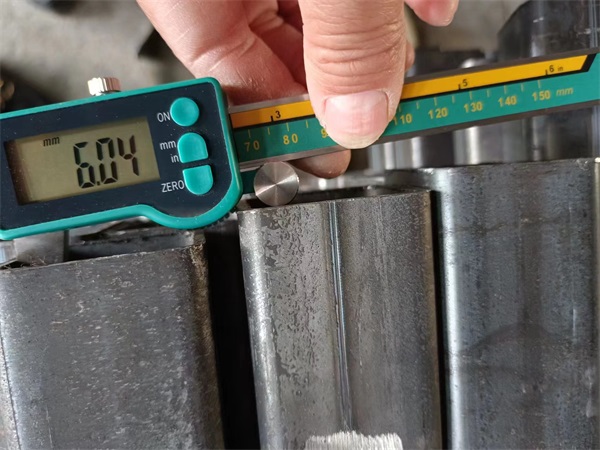

One significant aspect that needs to be assessed is the quality control procedures and standards implemented by LY Steel. Faults in the production process or insufficient quality checks can contribute to the production of defective rebar products. Understanding the role of these procedures is essential in effectively addressing and preventing future defects.

b. Material Composition and Processing Techniques

Another crucial aspect to consider when examining the causes of LY Steel Rebar Defective Products is the choice of materials and processing techniques. Substandard raw materials or improper processing can result in weak or faulty rebar. Analyzing the material composition and processing techniques provides valuable insights into the reasons behind the defects.

c. Environmental and External Factors

LY Steel Rebar Defective Products may also be influenced by external factors such as environmental conditions during manufacturing or transportation. Unfavorable conditions, including excessive heat or humidity, can affect the quality of rebar. It is imperative to investigate how these factors might have contributed to the emergence of defective products.

3. Impact of LY Steel Rebar Defective Products

a. Safety Concerns

The use of defective rebar in construction projects raises significant safety concerns. Weak or improperly manufactured rebar can compromise the structural integrity of buildings and infrastructure, potentially leading to catastrophic incidents. The extent of these safety concerns should be thoroughly examined to ensure public safety.

b. Economic Consequences

LY Steel Rebar Defective Products have had far-reaching economic consequences. Project delays, legal disputes, and the need for rework contribute to increased costs and financial losses. The impact on construction companies, investors, and the overall economy requires careful  consideration.

consideration.

c. Reputational Damage

The prevalence of LY Steel Rebar Defective Products has tarnished the company's reputation. Trust and confidence in the brand have been compromised, adversely affecting the company's relationship with customers and industry partners. The consequences of reputational damage should not be underestimated and should be addressed in any remedial actions.

4. Strategies to Address LY Steel Rebar Defective Products

a. Strengthened Quality Control Measures

To prevent future occurrences of defective rebar, LY Steel must enhance its quality control procedures. This includes implementing more stringent quality checks at various stages of production and investing in advanced testing technologies to ensure the integrity of their products.

b. Collaborative Efforts with Industry Stakeholders

Addressing the issue of LY Steel Rebar Defective Products requires collaborative efforts from all stakeholders involved in the construction industry. By fostering open dialogue and cooperation with contractors, engineers, and regulatory bodies, LY Steel can improve industry-wide quality standards and ensure safer construction practices.

c. Transparency and Accountability

LY Steel must embrace transparency and take responsibility for the defects in their products. This includes providing accurate information about the extent of the issue, collaborating with customers to rectify the situation, and being accountable for any damages caused by their defective products.

Conclusion:

In conclusion, the LY Steel Rebar Defective Products issue has significant implications for the construction industry. Analyzing the causes, understanding the impact, and formulating effective strategies to address the problem are all crucial steps towards ensuring the safety and quality of construction projects. By prioritizing quality control, fostering collaboration, and embracing transparency, the issue can be effectively resolved, restoring trust in LY Steel and the overall industry.