introduction

Abstract:

The cold cutting machine is a specialized tool used for cutting rebar. It offers numerous advantages over traditional cutting methods, such as increased precision, improved efficiency, and reduced labor costs. This article aims to delve into the various aspects of cold cutting machines in cutting rebar, providing readers with an in-depth understanding of its functioning, applications, advantages, and future prospects.

Text:

1. Introduction

1.1 Definition and Background

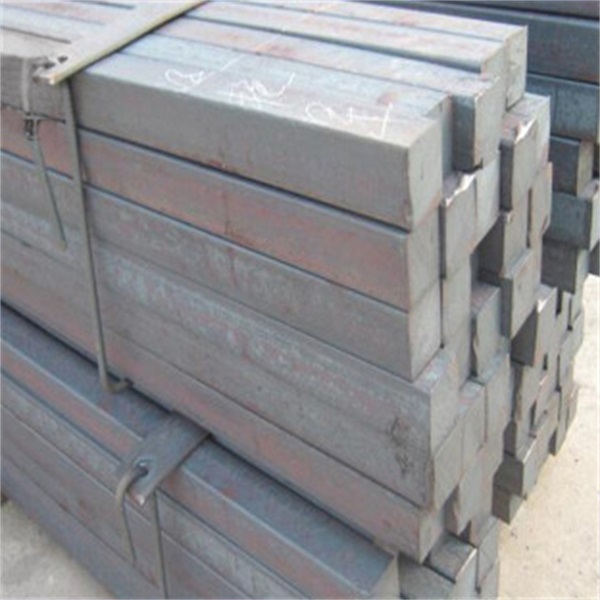

Rebar, short for reinforcing bar, plays a crucial role in construction projects, providing structural integrity and strength to concrete elements. It is essential to cut rebar accurately and efficiently. The cold cutting machine is a state-of-the-art tool specifically designed for this purpose. This section will provide a definition of the cold cutting machine, its historical background, and its importance in the construction industry.

1.2 Objectives of Cold Cutting Machines

Cold cutting machines are primarily aimed at achieving precise cuts on rebar without generating sparks or heat. They offer a safer alternative to conventional cutting methods that involve heat and potential fire hazards. Additionally, these machines excel in maintaining the integrity of the rebar’s structural properties. This section will explore the objectives and key features of cold cutting machines.

1.3 Overview of Cold Cutting Machine Applications

Cold cutting machines have a wide range of applications across various industries, including construction, manufacturing, and infrastructure development. This section will discuss the different areas where cold cutting machines are utilized, highlighting their versatility and effectiveness.

2. Working Principles of Cold Cutting Machines

2.1 Mechanical Components

Cold cutting machines consist of several mechanical components that work together to achieve precise and efficient cuts. This section will introduce the key components, such as the cutting blades, hydraulic systems, and control panels, explaining their functions and interactions.

2.2 Cutting Process

The cutting process in cold cutting machines involves a series of steps, each contributing to the overall efficiency and accuracy of the operation. This section will provide a step-by-step explanation of the cutting process, from positioning the rebar to executing the cut. It will also highlight the advantages of cold cutting machines over traditional methods.

2.3 Safety Measures

Ensuring safety during the cutting process is paramount. Cold cutting machines incorporate various safety features to protect operators and bystanders from potential risks. This section will discuss the safety measures implemented in these machines, such as emergency stop buttons, protective shields, and operator training.

3. Advantages of Cold Cutting Machines

3.1 Precision and Accuracy

One of the most significant advantages of cold cutting machines is their ability to achieve precise cuts with minimal deviations. This section will elaborate on the precision and accuracy offered by these machines, emphasizing their contribution to high-quality construction projects.

3.2 Efficiency and Productivity

Cold cutting machines streamline the cutting process, significantly reducing time and labor costs. Their efficiency and productivity advantages arise from their automated operations and rapid cutting speeds. This section will explore how cold cutting machines enhance productivity and optimize project timelines.

3.3 Cost-effectiveness

Cold cutting machines provide cost-effective solutions in the long run, primarily due to their ability to extend the lifespan of cutting tools and minimize rebar wastage. This section will discuss the cost-saving benefits offered by cold cutting machines, including reduced tool replacement expenses and enhanced material utilization.

4. Future prospects and advancements

4.1 Technological Innovations

Continuous advancements in cold cutting machine technology have the potential to revolutionize the construction industry. This section will discuss the cutting-edge technologies currently being developed and their potential impact on cold cutting machine capabilities and applications.

4.2 Environmental Considerations

In an era focused on sustainability, cold cutting machines offer environmentally friendly alternatives to traditional cutting methods. This section will explore how cold cutting machines contribute to reducing harmful emissions, minimizing waste generation, and promoting eco-friendly practices in the construction sector.

4.3 Future Applications

With ongoing research and development, cold cutting machines are expected to find new applications beyond rebar cutting. This section will speculate on potential future applications, including cutting other materials, integration with robotics, and advancements in automation.

Conclusion:

In conclusion, cold cutting machines play a vital role in the construction industry by ensuring precise and efficient cutting of rebar. The advantages they offer, such as enhanced precision, improved productivity, cost-effectiveness, and environmental friendliness, make them a practical choice for construction projects. As technology continues to evolve, the future  of cold cutting machines holds promising prospects for further advancements and diversified applications. By embracing these machines, the construction industry can benefit from safer and more efficient rebar cutting processes.

of cold cutting machines holds promising prospects for further advancements and diversified applications. By embracing these machines, the construction industry can benefit from safer and more efficient rebar cutting processes.